Products

ASPA is a manufacturer of high-quality metal welding systems. Check out ASPA's wide range of welding machines.

Service and training

We offer comprehensive maintenance services. Our staff is able to meet the requirements of the most demanding customers.

Services

By using our experience and knowledge of electrical engineering and mechanical engineering, we provide services at the highest level.

Learn more

about ASPA

ASPA is the leading manufacturer of resistance welding machines in Poland. The company's high position on the Polish and foreign markets stems from more than 60 years of tradition and extensive experience in the design and manufacture of metal welding equipment. With its own design and research department, ASPA constantly creates new technological solutions and introduces them in thousands of devices and welding stations located throughout Poland and Central and Eastern Europe.

Currently, we are Poland's largest manufacturer of spot, multipoint, hump, butt and tack welding machines, linear and tick welding machines, as well as complete welding lines and special equipment.

Specialized welding machines

Multi point welders for steel meshes made of smooth or ribbed steel bars are among the specialized equipment we manufacture. Our welding machines are used in the production of panels as well as fencing and reinforcement meshes. They provide high efficiency and precision welding.

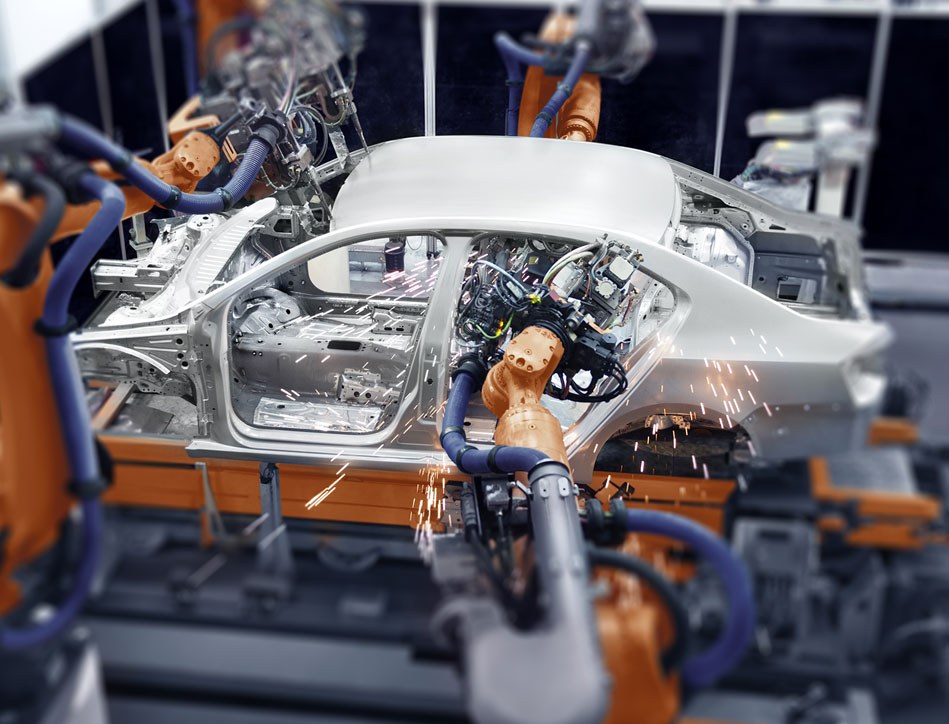

The high and very precise requirements that automobile manufacturers place on subcontractors supplying welded body assemblies and equipment, affect the need for specialized equipment to produce such components. The goal, therefore, is to obtain the quality of welds and the required precision in the positioning of components relative to each other so as to ensure the reliability and durability of the entire assembly, in accordance with the stringent requirements of automotive standards.

Our company's welding machines are widely used in the household appliance industry in the production of components for all kinds of stoves, ovens, refrigerators, washing machines, centrifuges, dishwashers or a whole range of large household appliances. In the production of components for these appliances, modified hump and in-line welding machines are most often used, but specialized welding equipment and automated stations equipped with industrial robots are also made.

The welding machines manufactured by our company are ideal for the production of such items as steel window frames, door frames, steel lock and bracket components or metal hinges in doors and windows, among others. Spot welders are also used in the welding of steel doors, their sheathing and steel garage doors.

Spot and hump welders are the most commonly used in this industry. On the special order of one of our clients representing the furniture industry, ASPA also made an automated station with industrial robots.

ASPA has in its portfolio a number of machines dedicated to the transportation industry. Leading Polish and European manufacturers of urban and intercity transport vehicles and freight transport are requesting welding machines specialized in both mass transport and freight transport.

The welding stations for wall elements and car roofs that we manufacture are evidence of ASPA's many years of experience in the design and construction of equipment in the automotive and transportation industries. Wagon wall and roof welding stations equipped with ZP4PS and ZG6PS DC welding machines are the best examples of equipment built to the special order of specific customers.

Welding of fuselage skins is performed using a spot welder that meets the stringent requirements of the aerospace industry, including monitoring of each weld with a parameter report. Welding of aluminum, stainless steel and titanium.

Development and projects

Cyber Micro Weld

The main objective of the project is to develop a new product - an innovative multipoint welding machine, which we plan to achieve as a result of the planned R&D work. This work has been divided into 4 stages, which include industrial research and development. These will include the development and testing of key elements of the technology, prototypes of the device will be made and tests will be carried out in real conditions. The designed solution will be implemented into the business activities of the Applicant, significantly increasing the competitiveness and innovativeness of our company against the entire industry.

This proposed solution is designed to eliminate key and common technological problems in welders known on the market. The new solution allows the use of an electronic circuit that switches the current between the different branches of the tool, pressing all the welded parts together at the same time. This will create micro-cycles of welding, the frequency of which - depending on individual cases - will range from 10 Hz to 10 kHz.

Title of the project: Grant for working capital for Przedsiębiorstwo Aparatury Spajalniczej ASPA Sp. z o.o..

Planned effects of the project: Maintaining the operation of the enterprise.

Total project value: 202 235.31 PLN

European Funds contribution: 202 235.31 PLN

Beneficiary: PRZEDSIĘBIORSTWA APARATURY SPAJALNICZE ASPA SPÓŁKA Z OGRANICZONĄ ODPOWIEDZIALNOŚCIĄ