- Products

- »

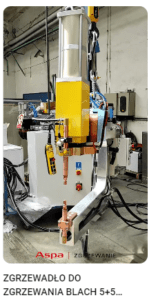

- Specialized welding machines

- »

- Railroads and streetcars

ASPA has a number of machines in its portfolio dedicated to the transportation industry. Leading Polish and European manufacturers of urban and intercity transport vehicles and freight transport are in demand for welders specialized in both mass transport and freight transport.

The welding stations for wall elements and car roofs that we manufacture are evidence of ASPA’s many years of experience in the design and construction of equipment in the automotive and transportation industries. Wagon wall and roof welding stations equipped with ZP4PS and ZG6PS DC welding machines are the best example of equipment built to the special order of specific customers.

These welders allow DC resistance welding of materials that are difficult to weld, including some alloy steels, brass or aluminum. The ZP4PS welder allows welding to flat sheet metal, such as a wagon wall with maximum dimensions of 6,000 mm x 1,000 mm, as well as reinforcing, spacer and support brackets. The assembly to be welded (built from pre-connected elements), fixed with hand clamps, performs longitudinal travel, and the welder moves perpendicular to the table.

The ZP6PS welder, on the other hand, allows welding to flat sheet metal, such as a wagon wall with maximum dimensions of 18,000 mm x 2,200 mm, as well as reinforcing, spacer and support brackets. The assembly to be welded (built from pre-connected elements), fixed with pneumatic clamps, performs longitudinal movement, and the welder moves perpendicular to the table.

Below are links to examples of our implementations: