- Products

- »

- Standard welding machines

- »

- Diffusion welders

Diffusion welding

In today’s dynamic world of materials engineering, there are many advanced technologies for joining different materials to achieve durable and effective joints. One fascinating process is diffusion welding, which enables materials to be joined at the microstructural level, resulting in exceptional durability and performance of the parts being joined.

What is diffusion welding?

Diffusion welding is the process of joining materials using high temperature and time, which allows atoms to migrate between the grain boundaries of the material. The result is diffusion, or the movement of atoms from an area of higher concentration to an area of lower concentration. This process allows for the formation of a homogeneous bond between materials, leading to a durable and strong connection.

It is a durable, accurate and precise method that allows materials with different properties to be joined together. It is a process of joining in a solid state , at an elevated temperature and under pressure. The welding process does not cause macroscopic deformation and mutual displacement of welded parts.

What materials can be joined?

The diffusion welding process is particularly effective for joining metals, but it can also be used to join metal to ceramics or composites. This makes it useful in a wide range of fields, such as aerospace, automotive, energy and medicine.

Advantages of diffusion welding:

➤ Durability: Joints achieved by diffusion welding are much more durable than other methods of joining materials.

➤ No additional materials: There is no need for additional materials such as binders or solders.

➤ Multi-material : The process allows a wide variety of materials to be joined, increasing its versatility.

Diffusion welding is one of the advanced material joining technologies that opens up new possibilities in the design and manufacture of advanced structures. With this process, engineers can achieve joints of exceptional strength and durability, a key element in today’s advanced technologies.

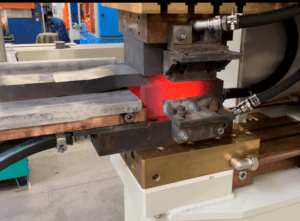

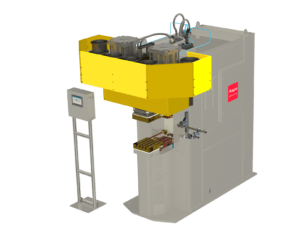

Diffusion welding machine for joining metals made by ASPA with control of time, current, pressure and also temperature of materials.

Based on an inverter current source.

Based on an inverter current source.

Diffusion welding capacity up to 15000 mm2.