- About Us

-

Products

-

Standard welding machines

Specialized welding machines

Industrial equipment

-

-

Services

-

Support

-

Spare parts

- Innovations

- Shop

- Careers

- Contact Us

- Butt welding machines

- Spot welding machines

- Spot welding table machines

- Spot and projection welders

- Projection welders

- Spot welding guns

- Linear welding machines

- Workshop welding machines

- Friction welders

- Diffusion welders

- Construction industry

- Automotive industry

- Domestic appliances

- Furniture industry

- Railroads and streetcars

- Aviation industry

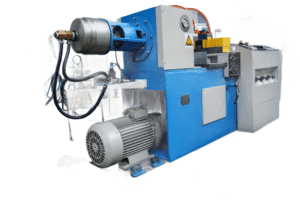

Friction welders

ASPA Product Catalog

- Products

- »

- Standard welding machines

- »

- Friction welders

Friction welding is a process in which the heat needed to join parts is generated by friction in the contact area of the objects to be welded. The mechanical energy of the motion of one workpiece, which rotates around an axis or performs a reciprocating motion relative to the other workpiece, is converted into heat energy. Thus, with sufficient pressure, the temperature in the friction area rises to a level sufficient to weld the metals, but below their melting point.

During welding, the parts are pressed against each other with a certain frictional force, which allows for controlled heat release. The process continues until the welded surfaces reach the required temperature. Then the relative motion of the workpieces stops, and the pressing force results in a permanent solid metallic bond. If local melting of the contact surface occurs, the liquid metal is pushed outward, but the final connection also occurs in the solid state.

Friction welding technology provides high joint reliability and process control, which minimizes the risk of weld defects and increases production efficiency.