- Products

- »

- Standard welding machines

- »

- Linear welding machines

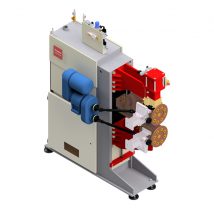

Linear welding machines

Linear welding machines manufactured by ASPA are irreplaceable in the process of linear welding of sheet metal and other workpieces made of low-carbon steel and some alloy steels. In addition, these advanced devices allow spot welding of workpieces, which increases their versatility. Thanks to the use of modern microprocessor control systems, ASPA welders offer extremely precise selection of welding parameters. This makes it possible to achieve welds of the highest quality, while maintaining the efficiency of the process. The additional diagnostic systems with which these machines are equipped ensure high productivity and operational safety.

Versatility and Specialized Applications

ASPA’s in-line welding machines enable metals to be joined using a sequence of welds performed one after the other by rotating copper alloy disks. They are ideal for longitudinal or transverse welding of cylindrical containers, fire extinguishers, radiators, tanks, filters and other similar components, while providing excellent quality results.

The units can be customized to meet any specific welding requirements. Versions with three-phase DC power supply and medium-frequency DC inverter (1000 Hz) are also available upon request. Mid-frequency welders can achieve exceptionally high quality welds at significantly increased welding speeds, which is ideal for joining thin sheets and filter nets with minimal distortion.

Operating Principle and Typical Joints

In-line welding is a welding process using electrical resistance. In this method, overlapping metals are welded under pressure using a sequence of points, which are made with rotating copper alloy discs. Depending on the choice of parameters, such as spot frequency and electrode speed, two typical joints can be obtained:

- Watertight Welding: Achieved by selecting a short welding time with a long break time, which allows two metals to be joined without watertight welding.

- Watertight Welding: Achieved by adjusting the welding time and gap so that each point overlaps the next, allowing watertight joints.

ASPA in-line welders are the ideal solution for companies looking for reliable, precise and efficient welding equipment. Thanks to their advanced technology and versatility, they meet the highest standards of quality and safety, adapting to individual user needs.